Supervisor/Coordinator: Paul A. Janmey, Karen I. Winey, Paulo Arratia and Arjun G. Yodh

Equipment:

Confocal Rheometer

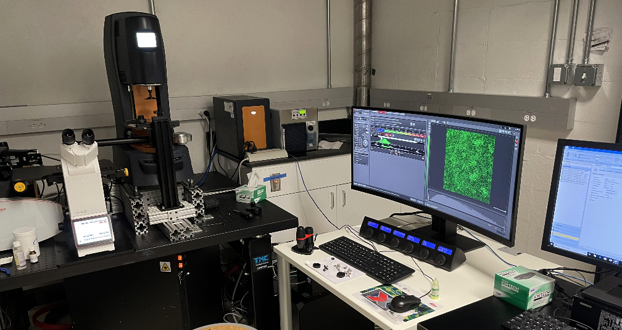

Faculty advisor: Paulo E. Arratia The LRSM possess a state-of-the-art confocal rheometer microscope equipped with a confocal microscope (Leica Stellaris) and a stress-controlled rheometer (TA Instrument DHR-3). This apparatus allows researchers to impose precise kinematic deformation onto a desired material while simultaneously characterizing the fluid microstructure and measuring the bulk fluid response.

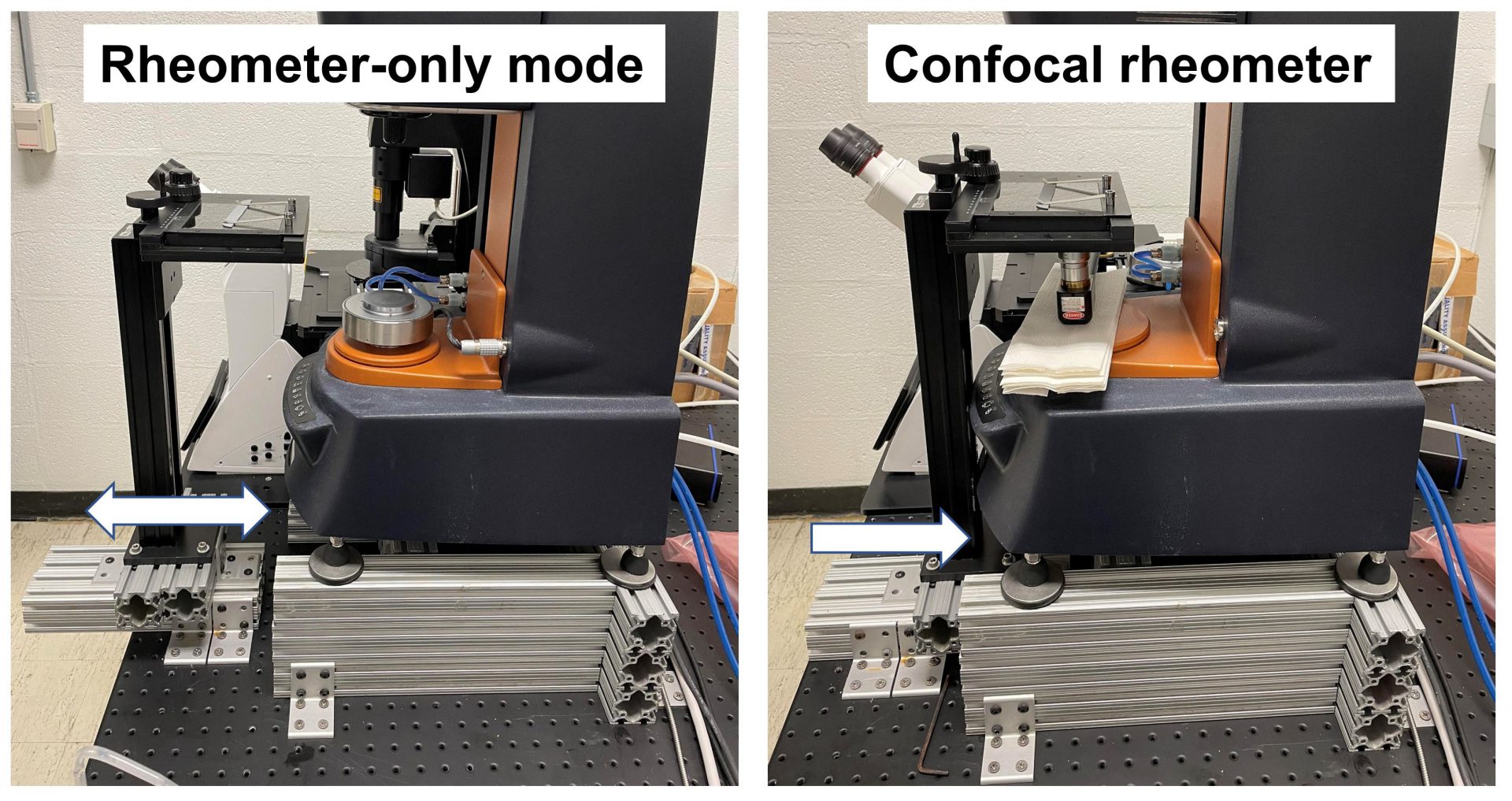

The image above is of the detachable confocal rheometer setup. Left: The confocal rheometer setup in rheometry mode with the imaging stage positioned away from the rheometer. Right: The movable imaging stage-cum-bottom geometry aligned with the objective extender from confocal microscope and top geometry for confocal rheometry experiments.

The confocal microscope (Leica Stellaris) works by packaging a variable wavelength laser and a photo-multiplier detector into a single unit. With high precision, rapid motion of the objective (above 8KHz), achieved by harnessing a piezoelectric element, three dimensional (3D) scans (256 x 256 x 100 voxels) of a material’s structure can be created. Of key importance is that the scan be completed more rapidly than the time scales of imposed stress from the rheometer, ensuring minimal sample motion during the scan.

A TA Instrument DHR-3 rheometer is integrated to the confocal microscope. This hybrid rheometer is amenable to imaging via an off-the-shelf accessory and in-house optical manipulation. The DHR-3 provides good measurement quality for a variety of rheological tests and can resolve a torque range of 0.5nN.m to 200mN.m, with changeable geometries adding another two orders of magnitude to the range of detectable stresses. This is an important feature in providing enough dynamical rage from low to high viscosity samples.

TA Instruments RFS II

Faculty advisor: Paul A. Janmey This facility is capable of characterizing both the structure and flow properties of simple and complex fluids. It can solve the most demanding fluid rheology problems including dynamic oscillatory and shear rate controlled measurements on low viscosity structured fluids. It is equipped with:

Faculty advisor: Paul A. Janmey This facility is capable of characterizing both the structure and flow properties of simple and complex fluids. It can solve the most demanding fluid rheology problems including dynamic oscillatory and shear rate controlled measurements on low viscosity structured fluids. It is equipped with:

- Peltier plate temperature control (from -30oC to 150 oC)

- Recirculating fluid bath (from -10 oC to 140 oC)

- Forced convection oven

- Torque ranges from 0.002 to 1000 g.cm

- Frequency ranges from 10-5 to 500 rad/sec

Bohlin Gemini

Faculty advisor: Paulo E. Arratia, facility contact: Shravan Pradeep

Faculty advisor: Paulo E. Arratia, facility contact: Shravan Pradeep

The Bohlin Gemini rheometer is optimized for both stress controlled and strain controlled measurements. Technical features include a broad torque range, which extends to 200 mNm. The high-resolution torque mapping system applied to Bohlin’s low bias air bearing technology allows low torques to be set extremely accurately. The Bohlin is ideal for stress or strain controlled measurements of viscoelastic fluids with shear modulus as low as 1mPa. Couple with Nikon Eclipse 200/Confocal VT Eye microscopy for in-situ imaging during shearing (see details below)

Haake CaBER

Faculty advisor: Paulo E. Arratia, facility contact: Shravan Pradeep

Faculty advisor: Paulo E. Arratia, facility contact: Shravan Pradeep

The Haake CaBer (capillary break-up extensional rheometer) provides valuable information about a material’s extensional properties that rotational rheometers cannot provide. With the CaBER, stringiness, filaments break-up time and extensional viscosity can be quantified.

Nikon Eclipse 200/Confocal VT Eye

Faculty advisor: Arjun G. Yodh

Inverted light microscope, capable of fluorescence microscopy. This microscope is attached to a VisiTech ‘VT-Eye’ confocal setup, and Bohlin Gemini rheometer. VisiTech ‘VT-Eye’

- 30 images per second (512 x 512 pixels); up to 400 images/s for reduced field of view

- Ultra-fast 3D acquisition: 256 x 256 x 100 pixel 3D image, 1 per second

- Z-scan up to 100 microns with 100 nm resolution

- Multi- wavelength excitation laser, at 488, 569 and 633 nm

- Reflection mode capability

- VoxCell software for easy control and data management

Instron Model 5564 Table Mounted Materials Testing System

Faculty advisor: Karen I. Winey This facility is capable of performing tensile, compression, peel, and flexural tests on most materials and components. It is equipped with:

Faculty advisor: Karen I. Winey This facility is capable of performing tensile, compression, peel, and flexural tests on most materials and components. It is equipped with:

- 2 tension/compression load cells with capacity of 2kN and 10N, respectively.

- 1 rigid coupling.

- 1 micro 3-point bend fixture.

- 2 stainless steel tensile grips with 100lb capacity.

- 1 double-walled saline immersion vessel with digital temperature controller.

Facilities users must include the following text in the acknowledgment section of their publications:

“The authors acknowledge the use of facilities supported by the Laboratory for Research on the Structure of Matter and the NSF through the University of Pennsylvania Materials Research Science and Engineering Center (MRSEC) DMR-2309043.”